In the world of maintenance, manufacturing, and mechanical engineering, lubrication is essential to ensure the smooth operation of machinery and equipment. Among the many types of lubricants available, PTFE (polytetrafluoroethylene) lubricant stands out for its unique properties and versatility. One brand that has gained significant attention in this field is Super Lube PTFE lubricant.

Understanding PTFE Lubricant

PTFE, commonly known by the brand name Teflon, is a synthetic fluoropolymer of tetrafluoroethylene. Discovered in 1938, PTFE has become a staple material in various industries due to its remarkable properties. PTFE is best known for its non-stick qualities, high resistance to heat, chemicals, and its low coefficient of friction. When used as a lubricant, PTFE can reduce wear and tear on surfaces, minimize friction, and extend the lifespan of mechanical components.

PTFE lubricants come in various forms, including oils, greases, and dry sprays. The choice of form depends on the specific application and the environment in which it will be used. Regardless of the form, PTFE lubricants offer exceptional performance, making them ideal for a wide range of uses.

Why Choose Super Lube PTFE Lubricant?

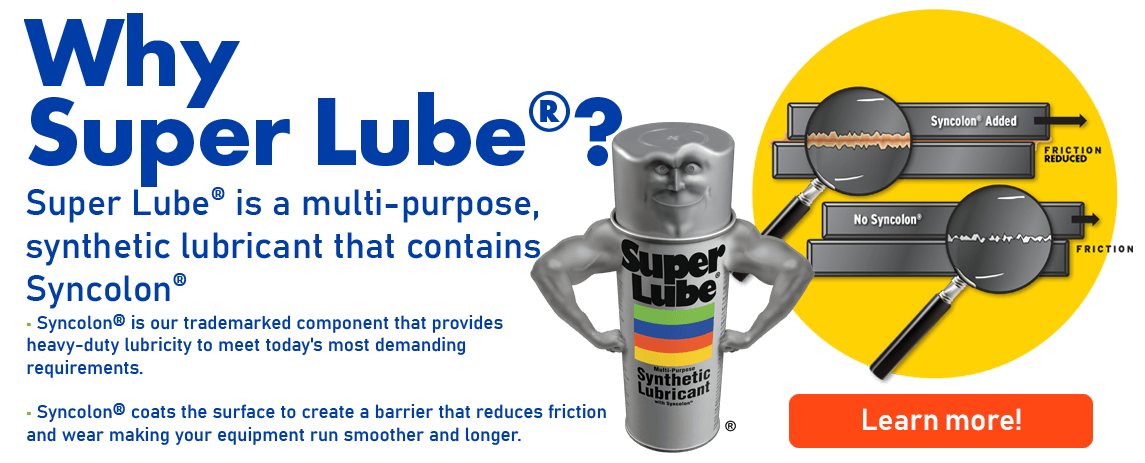

Super Lube is a well-known brand that produces a variety of synthetic lubricants enhanced with PTFE. What sets Super Lube apart from other PTFE lubricants is its advanced formulation, which combines synthetic base oils with micron-sized particles of PTFE. This combination provides superior lubrication, reduced friction, and enhanced protection against wear.

Super Lube PTFE lubricant is also designed to be multi-purpose, making it suitable for a wide range of applications across different industries. Whether you’re dealing with heavy machinery, automotive parts, or household tools, Super Lube PTFE lubricant can provide reliable performance and long-lasting protection.

Common Applications of Super Lube PTFE Lubricant

Industrial Machinery

In industrial settings, machinery and equipment are subjected to intense stress and high operational demands. Super Lube PTFE lubricant plays a crucial role in reducing friction between moving parts, minimizing wear and tear, and ensuring smooth operation. The low friction properties of Super Lube's PTFE formulation ensure that machines run efficiently, with minimal downtime and reduced maintenance costs.

Super Lube PTFE lubricant is also highly resistant to chemicals, making it ideal for use in industries such as chemical processing, pharmaceuticals, and food production. Its ability to withstand exposure to corrosive substances ensures that machinery remains protected and operational, even in harsh conditions.

Automotive Industry

The automotive industry relies heavily on PTFE lubricants for various applications, and Super Lube is a top choice for many professionals. Super Lube PTFE lubricant is used to lubricate automotive parts such as bearings, gears, and chains. Its ability to withstand high temperatures and resist water makes it an excellent choice for automotive applications where components are exposed to extreme conditions.

Additionally, Super Lube PTFE lubricant is often used in car care products, such as engine oils and brake lubricants. These products help reduce friction within the engine, improve fuel efficiency, and prolong the life of critical components. The non-stick properties of Super Lube's PTFE formulation also make it ideal for preventing the buildup of dirt and debris on car parts, ensuring smoother operation and easier maintenance.

Household and DIY Applications

Super Lube PTFE lubricant is not limited to industrial and automotive uses; it is also incredibly useful for household and DIY projects. Whether you're fixing a squeaky door hinge, lubricating a bicycle chain, or maintaining garden tools, Super Lube PTFE lubricant can help. Its versatility makes it suitable for a wide range of applications around the home.

One of the key benefits of Super Lube PTFE lubricant in household settings is its non-stick properties. When applied to surfaces, it forms a protective barrier that repels dirt, water, and other contaminants. This makes cleaning and maintenance easier and extends the life of tools and equipment. Super Lube PTFE lubricant is also safe to use on a variety of materials, including metal, plastic, and rubber, making it a go-to solution for DIY enthusiasts.

Marine and Aerospace Industries

In the marine and aerospace industries, components are often exposed to extreme conditions, including saltwater, high humidity, and extreme temperatures. Super Lube PTFE lubricant is well-suited for these environments due to its exceptional resistance to corrosion, water, and chemicals. In marine applications, Super Lube PTFE lubricant is commonly used to lubricate boat engines, propellers, and other components exposed to seawater.

In aerospace, Super Lube PTFE lubricant is used in the manufacture and maintenance of aircraft components. Its ability to function effectively in high-pressure and high-temperature environments makes it indispensable in this industry. Super Lube PTFE lubricant ensures that critical components, such as landing gear, turbines, and control systems, operate smoothly and reliably, even under the most challenging conditions.

Electronics and Electrical Applications

Super Lube PTFE lubricants are also used in electronics and electrical applications, where reducing friction and preventing corrosion are essential. For instance, they can be used to lubricate connectors, switches, and other moving parts in electronic devices. The non-conductive properties of Super Lube PTFE ensure that it does not interfere with electrical signals, making it safe for use in sensitive electronic equipment.

Additionally, Super Lube's ability to resist high temperatures makes it suitable for use in electrical insulation. It can be applied to wires and cables to protect them from heat and wear, ensuring that they remain functional and safe over time.

Benefits of Using Super Lube PTFE Lubricant

The widespread use of Super Lube PTFE lubricant across various industries is a testament to its numerous benefits. Some of the key advantages include:

Superior Lubrication: The advanced formulation of Super Lube combines synthetic oils with PTFE particles, providing exceptional lubrication and reducing wear.

Multi-Purpose Application: Super Lube PTFE lubricant is versatile and can be used in various industries, from automotive to electronics, making it a reliable choice for multiple needs.

High-Temperature Stability: Super Lube PTFE lubricant can withstand extreme temperatures, making it suitable for applications where heat resistance is critical.

Non-Stick Properties: Super Lube forms a protective barrier on surfaces, preventing the buildup of dirt, debris, and contaminants.

Long-Lasting Protection: Super Lube PTFE lubricant provides long-lasting protection, reducing the need for frequent reapplication and lowering maintenance costs.

Conclusion

Super Lube PTFE lubricant is a versatile and reliable solution for reducing friction, preventing wear, and protecting components in a wide range of applications. Whether you're working in an industrial setting, maintaining automotive parts, or tackling household repairs, Super Lube PTFE lubricant can help you achieve better performance and longer-lasting results. Its unique formulation, which includes synthetic base oils and PTFE particles, offers superior lubrication, chemical resistance, and high-temperature stability. When choosing a lubricant, consider the benefits of Super Lube PTFE and how it can enhance the performance of your machinery, tools, and equipment.

Leave a comment

All comments are moderated before being published.

Situs ini dilindungi oleh reCAPTCHA dan berlaku Kebijakan Privasi dan Persyaratan Layanan Google.